High transparent medical grade Polypropylene PP 5090T

High transparent medical grade Polypropylene PP 5090T

Product parameters

| Performance of the project | The test conditions | The test method | The test data | The data unit |

| Melt flow rate | / | ISO 1133 | 9 | g/10min |

| Shrinkage | / | FPC Method | 1.3-1.7 | % |

| The density of | / | ISO 1183 | 0.9 | g/cm3 |

| Tensile yield strength | / | ISO 527 | 29 | MPa |

| Elongation at breaking point | / | ISO 527 | 200 | % |

| Rockwell hardness | / | ISO 2039 | 105 | R |

| Mechanical properties of |

||||

| Bending modulus | / | ISO 178 | 1422 | MPa |

| IZOD notch impact strength | 23℃ | ISO 180 | 10 | kg.cm/cm |

| IZOD notch impact strength | -20℃ | ISO 180 | 4.5 | ISO 180 |

| Thermal deformation temperature | / | ISO 75 | 130 | ℃ |

| Thermal performance |

||||

| Veka softening point | / | ISO 306 | 155 | ℃ |

| Combustibility | Natural≥2mm | UL 94 | 94HB | Class |

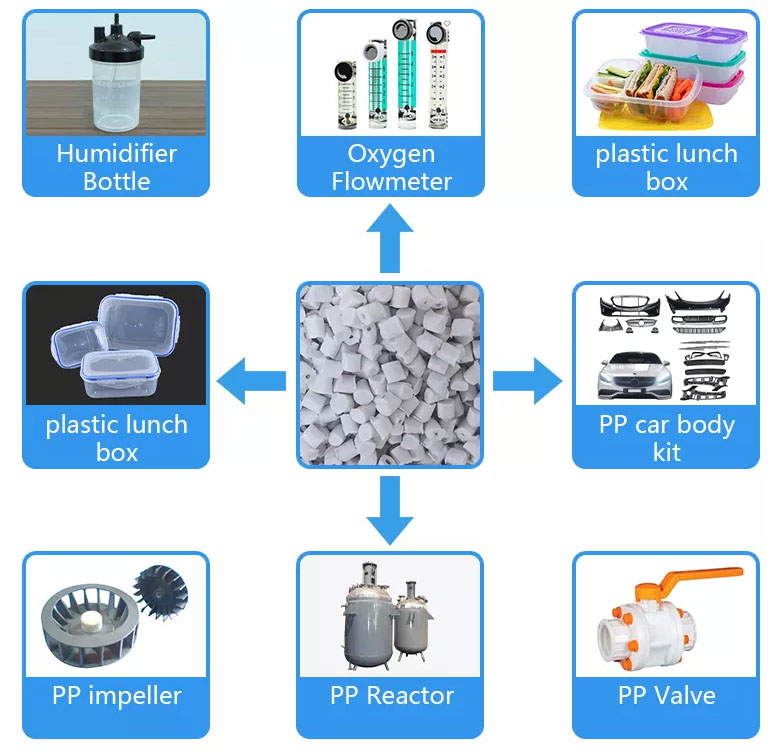

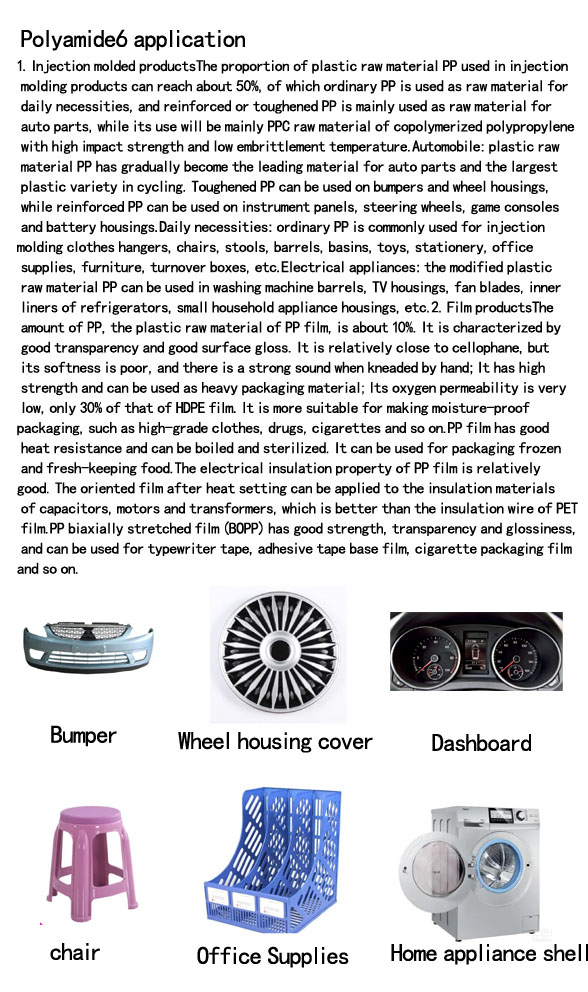

Applications

(ningbo) Taiwan Formosa Plastics pp5090t main uses:

PP is a semi crystalline material. It is harder than PE and has a higher melting point. Since homopolymer type PP is very brittle when the temperature is below 0 ℃, many commercial PP materials are random copolymers with 1-4% ethylene or clamp type copolymers with higher ethylene content. The copolymer type PP material has lower thermal distortion temperature (100 ℃), low transparency, low gloss and low rigidity, but has stronger impact strength.

The flow rate MFR of PP ranges from 1 to 40. PP with low MFR has better impact resistance but lower tensile strength. For materials with the same MFR, the strength of the copolymer type is higher than that of the homopolymer type. Due to crystallization, the shrinkage rate of PP is quite high, generally 1.8-2.5%. And the directional uniformity of shrinkage is much better than that of PE-HD and other materials. Adding 30% glass additive can reduce the shrinkage to 0.7%.

Homopolymer type and copolymer type PP materials have excellent moisture absorption resistance, acid-base corrosion resistance and dissolution resistance. However, it has no resistance to aromatic hydrocarbon (such as benzene) solvent and chlorinated hydrocarbon (carbon tetrachloride) solvent. PP does not have oxidation resistance at high temperature as PE does.

According to the above performance, PP is suitable for the following products:

1. Injection: valves, accessories, crates, automobiles, closures, electrical appliances, water bottles, food Containers, household goods, toys, non pre filled syringes.

2. Extrusion: thick sheet, sheet, pipe, straw, binding tape, stationery sheet, BOPP film Sheet and strip.

3. Blow molding: bottle.

4. Thermoforming: tray, bowl, jelly cup, water cup.

5. Flat yarn: woven bag, container bag, carpet.