Polypropylene Medical grade melt blown cloth material PP S2040

Polypropylene Medical grade melt blown cloth material PP S2040

Product Description

Homopolymer polypropylene is a polymer formed by polymerization of propylene monomer only. Homopolymer polypropylene is a semi crystalline polymer. Because of its high crystallinity, homopolymer polypropylene has excellent mechanical properties. Including high rigidity, high tensile strength, good heat resistance and deformation. At the same time, because of its good fluidity, high crystallization temperature shortens the molding cycle of products. Homopolymer polypropylene is widely used in injection, drawing and other processing and molding processes.

Physical Properties

Melt Flow Rate (230℃/2.16 kg) 36.0 g/10min

Density 0.90 g/cm 3

Melting Temperature (DSC) 162 ℃

Mechanical Properties

Tensile Strength at Yield (50 mm/min) 33 MPa

Tensile Strength at Break (50 mm/min) 20 MPa

Tensile Elongation at Break (50 mm/min) 600 %

Flexural Modulus (2 mm/min) 1300 MPa

Charpy Impact Strength, notched (23℃) 2.5 kJ/m2

Thermal Properties

Heat Deflection Temperature (0.45 MPa) 83 ℃

Vicat Softening Point (A50) 151 ℃

Recommended processing temperature: 190 ~ 250℃

Applications

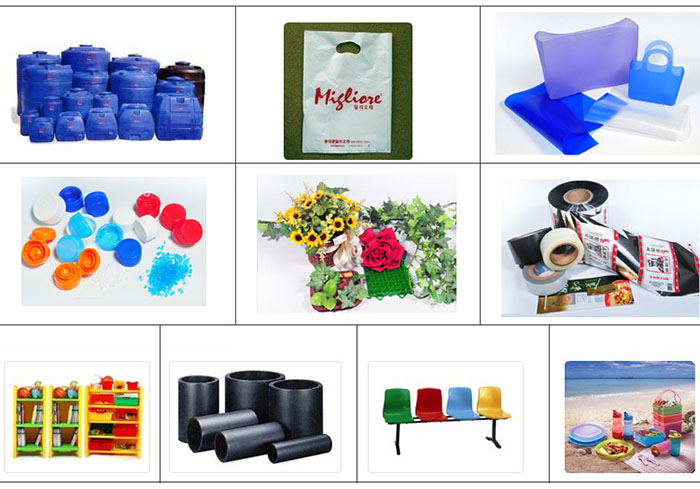

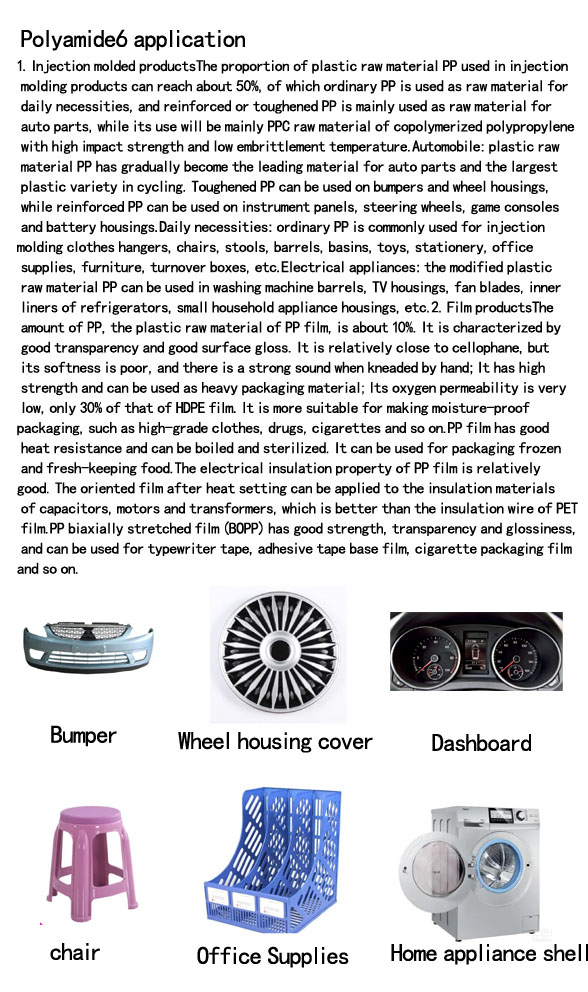

Application scope of homopolymer polypropylene:

1. Extrusion molding: pipes, plates, sheets, etc.

2. Injection molding: all kinds of containers and accessories, including food containers, household appliances, home appliance shells, etc.

3. Thermoforming: disposable tableware, including lunch boxes, bowls and plates, beverage cups, etc.

4. Film: Homopolymer polypropylene film is transparent and shiny, with little permeability to water vapor, including blown film, cast film, bidirectional extension film, etc.

5. Drawing: flat yarn can be produced with low fluidity, and compound yarn and non-woven fabric can be produced with high fluidity.

Fiber is the main market for polypropylene. Stretching or orienting can increase the tensile strength by 15 times. Silk products, including clothing, diapers and nonwovens, are the main raw materials for the production of medical masks Furniture Leather, Agricultural Bags, Ropes, Floor Covering Fabrics and Belts. Carpet and carpet back village. PP can also be cast or directionally stretched into films. Directional films can be used as cigarettes. Packaging materials for candy and many articles; Non oriented film is used for capacitors or packaging materials PP sheet is used to make thermoforming food containers, and its moisture-proof, gas transmission and odor transmission properties must comply with FDA regulations.